Spark The Electric Jester 2 Free Download PC game in a pre-installed direct link. Anti virus before extracting the game to prevent it from deleting the crack files. Euro Truck Simulator 2 - Wheel Tuning Pack Torrent Download hacked. Full crack Keygen Painkiller Hell amp; Damnation download for pc highly compressed.

- The MaptunerX Bundle delivers instant plug-in horsepower! Quickly and easily load performance tunes into your Sea-Doo SPARK eliminating the need to ship out your ECU for programming. Features a slick, full color, touch screen display. There is no limit to the number of vehicles or tunes you can reflash with the MaptunerX.

- The DIY Hunter goes over how to best operate the e-Pack Wheel while climbing up the mountain with around 150 lbs of gear.

This article will discuss the truing of the common spoked bicycle wheel.

1Getting Started

- Spoke Wrench, purchased to fit nipples.

- Spoke Tension Meter: TM-1

- Dishing Tool: WAG-4 or WAG-5, (necessary for the most accurate work)

- Light lubricant such as CL-1

- Rags

The wheels drive the bike forward when we pedal, allowing us to roll down the road or trail. Having wheels that spin straight and round adds to the bike’s performance. Spokes allow adjustments to the tension on the rim that will affect how straight the wheels spin. Some wheels use non-serviceable blades or a large disc rather than spokes. For most disc or blade model wheels there is no adjustment or repair possible other than replacement.

The wheels also help slow the bike. Rim caliper brakes, such as linear pull, cantilever, side pull, and dual pivot brakes use the rim sidewall as the braking surface. There may be problems during the ride and when braking if the wheel wobbles side to side, or is “out-of-true”. Brake pad adjustment will also be difficult with an out-of-true wheel.

The typical bicycle wheel is composed of a rim suspended with tensioned spokes around a center hub. Each spoke pulls on a section of rim. Spokes coming from the right side hub flange pull the rim to the right. Spokes coming from the left side hub flange pull the rim to the left. Spokes attached at the rim are then offset in a left-right-left-right pattern to counter the pull of the other side. Having all the spokes tight with fairly even tension makes the wheel true and strong. Changes to spoke tension will pull on the rim and affect its true. This process is called “truing”.

Truing is occasionally needed to keep the rim running straight as it spins between the brake pads. Spoke tension is adjusted by tightening or loosening a threaded nut, called the nipple, at the end of the spoke. Spoke threads typically use right-hand threads. Although a common phrase among mechanics is to “tighten the spokes”, it is the nipple that is turned, not the spokes.

To adjust tension at the nipple, first select the correct wrench. Spoke nipples are typically square, and come in different sizes. The correct wrench is the smallest size that can be used, even if it seems slow putting the wrench on the nipple. Make sure the wrench is fully engaged on the nipple before turning. A wrench that is partially engaged may damage the nipple and make truing difficult. For the commonly available Park Tool spoke wrenches, the smallest size is the black (SW-0), followed by the larger green (SW-1), and then red (SW-2).

- The SW-0 (black handle) is sized for 3.22mm (0.127″) nipples and fits Wheelsmith®, Marwi® and DT®, Edco® as well as other brands of nipples.

- The SW-1 (green handle) 3.3mm / 80 ga. / .130 nipple

- The SW-2 (red handle) 3.45mm / 80 ga. / .136 nipple

- The SW-3 (blue handle) 3.96mm / 105 ga. / .156 nipple

- For other spoke wrench choices see Wheel & Spoke Tool

When truing a wheel, the wrench and nipples may end up being viewed upside down. This happens if the wrench and nipple is viewed below the axle center. The wrench will appear to the mechanic as turning to the left when tightening the nipple. Do not allow this to confuse you. Keep in mind that the nipple is rotating around the fixed spoke, the spoke does not rotate. If in doubt, imagine a screwdriver at the nipple end, and turn it clockwise or counter-clockwise as needed.

There are four basic aspects of wheel truing. These are lateral true, radial true, rim centering over the hub, and spoke tension. Professional mechanics are able to adjust spoke tension so each aspect is optimal. Using truing stands, centering tools, spoke tensiometers, and experience, a professional will produce a durable and strong wheel.

LATERAL TRUE: this true is also called “rim run-out”, and is the side-to-side wobble of the rim as the wheel spins. This aspect is the most critical to brake caliper settings.

RADIAL TRUE: this is the amount of up and down wobble. If the wheel becomes out-of-round, it wobbles up and down with each revolution. In severe cases this will affect brake pad placement and can be felt by the rider as a bump every wheel revolution.

RIM CENTERING or “DISH”: this refers to the rim being centered in the frame. If the rim is offset in the frame to either side it may be difficult to adjust the brakes. Severe cases of poor centering can also cause handling problems, because the rear wheel will not track behind the front wheel.

TENSION: this is simply the tightness of the spokes. Spokes are tensioned just like other fasteners. Spoke tension is best measured using a tool called a spoke tension meter (tensiometer) such as the Park Tool TM-1, which flexes the spoke using a calibrated spring.

2Truing Procedure

The procedure described here emphasizes lateral true, which most affects the caliper brake. The idea is to get the wheels true enough to avoid hitting the brake pads. The other aspects of truing such as radial, centering and tension are important. For the novice mechanic, it is best to begin with lateral true in order for the brakes to work properly.

The image below is a “mechanic’s eye” view of the rim. The spoke nipples labeled A, C, and E are on the left side of the rim and come from the left side flange. Spoke nipples B, D, and F are on the right and come from the right side flange. Left side spokes tend to pull the rim toward the left. Their pulling is offset by the pull of spokes on the right. Each nipple effects relatively wide area of the rim. For example, spoke C will pulls mainly adjacent to its location, but will also effect the rim up to and even past A and F. Tightening nipple C increases spoke tension and moves that section of rim to the left. Tightening nipple D will tend to move the rim to the right. Loosening nipple C will also tend to move the rim to the right, because on the constant pull of D.

In order to see rim movement, a steady pointer is useful as a reference. A wheel-truing stand allows easier and more accurate work. It is also possible to use anything that can hold the wheel steady as a truing stand, such as the frame. A pointer can be created by using the brake pads. Radial truing and rim centering are typically not an issue when only minor corrections are made. It can help to remove the tire while truing.

- Remove wheel from bike and remove tire. (NOTE: for lateral truing, the tire can remain in place.)

- Mount wheel in truing stand, with right side of the wheel on the right side of the stand.

- Lubricate the threads of the spokes and where the nipple exits rim.

- Bring calipers up to rim level. Generally, place caliper tips close to outer end of braking surface.

- Spin wheel. Adjust caliper close to rim. Keep moving caliper until either side begins to lightly scrape rim. Only a light scrap is desired, bring caliper slightly away if scraping heavily.

- Stop wheel where rim and indicator are closest, at the point of the scrape.

- Rotate rim back and forth past caliper and find center of rim deviation.

- If the rim deviation is moving toward the indicator, this section of rim needs to move away from caliper.

- Tighten nipple 1/2 turn. Move wheel back and forth in this area and check deviation again.

- Spin wheel and locate another side-to-side deviation using indicator. Again slow and stop the rim where rim approaches indicator. Locate closest nipple opposite to center of deviation tighten nipple. If nipple appears especially tight, loosen spoke on same side as rub on indicator.

- Repeat until wheel is true. Wheel is adequately true if it wobbles less than 1/16″ (1.0mm).

- Clean rim braking surface with a solvent such as rubbing alcohol or a window cleaner.

Radial Truing

The wheel rim may appear to move in and out toward the center. Another way to view it is up and down. This radial aspect of the wheel can be affected by spoke tension. Sections of rim can be moved toward the hub by tightening spokes. Alternatively, sections of rim can move slightly outward by loosening spokes. It is typically best to work using pairs of spokes. By working with adjacent left-right spokes there is less of a tendency for the wheel to become laterally out of true.

- Remove wheel from bike and mount in a truing stand.

- Bring caliper close to lower outside edge of rim.

- Spin rim and bring calipers slowly closer to rim until there is a very light rub.

- Stop rim a light rub. Move rim back and forth through rub and locate center of deviation. This section of rim is relatively further from the hub than the rest of the rim. It needs to move closer to hub.

- Tighten the two spokes in the middle of the rub. Tighten each the same amount, beginning with 1/2 turn.

- Move the rim back and forth through the selected area. Repeat tightening if necessary.

- Spin the rim and move the calipers slightly closer to the rim. Correct rub by tightening a left-right pair at the center of the rub.

- After making three radial corrections, stop and double check lateral true. Correct lateral true as needed.

- After making several radial corrections by tightening, the rim may show only areas moving toward the hub. It is necessary to loosen these area to make the rim rounder.

- Spin the rim and move caliper for a light continuous scrape. The area not scraping are called low spots, or dips, and need to move away from the hub to be corrected. Isolate the center of the worst low spot

- Loosen two spoke on either side of the center of the low spot. Spokes should be adjacent left side-right side pairs.

- Repeat procedure on other low spots.

- Wheel is adequately trued for round when the deviation from the low spot to the highest spot is about 1/32 of an inch (about 0.5mm)

NOTE: If the wheel rim has been damaged and deformed from impact, such as during riding or even hipping, it may not be possible to correct the rim to a tight tolerance.

Centering or Dish Adjustment

The rim should be centered to the hub so that it sits adequately centered in the bike. If a rim appears to be centered in the front forks or the rear triangle, it is usually considered adequately centered. The most accurate method to check centering over a hub is with a dishing tool, such as the Park Tool WAG-4 or WAG-5. For detailed procedures see Wheel Dishing (Centering).

5

Spoke Tension

Spokes and nipples should be considered “fasteners”, like any nut and bolt. Generally, spokes should be as tight as the wheel allows. Too low of spoke tension tends to decrease spoke life by increasing the cycles of stress a wheel sees every time it rotates under the rider. Too high of tension may damage the rim or hub by pulling too much. The rim may develop cracks where the nipple exits the rim, or the hub flange may crack.

Spoke tension is best measured with a spoke tension meter (also called a tensiometer), such as the TM-1. It is possible to some degree to “feel” the tension by squeezing crossing or parallel spokes. The squeezing technique can be quite deceiving and inconsistent.

The TM-1 allows the user to determine both relative spoke tension between spokes and the tension force of each spoke. Spokes should be fairly close in relative tension and fully tight.

The tool gives a reading of deflection of the spoke. The TM-1 comes with a conversion table to convert the deflection reading to force. Broadly speaking spokes should be between 80 Kilograms force and as high as 230 Kilograms force. For more see Wheel Tension Measurement.

NOTE: There are some models of wheels where the nipple is located at the hub. These wheels true the same as conventional wheels. Tightening a spoke will draw the rim toward the hub flange side where it connects. The treading of the spokes and nipples is still a right-hand thread, and nipples tighten clockwise as seen for the orientation of the nipple. If the wheel has flat spokes, it is often necessary to hold the spoke flat close to the nipple with an adjustable wrench to keep the spoke from twisting.

6Wheel Wear, Damage and Repair

With enough use, especially in wet and dirty conditions, the rim surface can become ground down and thinned. The dirt and brake pad act as a grinder and wear on the metal. The tire, when under pressure, is held in place by the rim sidewall. A worn or thin sidewall may break or fail during a ride. Inspect the rim braking surface for a dished, concave appearance. The surface can also be inspected by running a finger along the braking surface. However, some rims are manufactured with a concave surface when new, so compare the front and rear rims. If they are the same rim models they should look and feel the same.

The lubrication of nipple threads should be done routinely because corrosion and rust in these threads will make the wheel un-trueable. Even if the wheel appears not to need any truing, lubricate at the threads monthly, and then clean the rims of any excess lubrication. Excess lubrication on the rim will affect the braking surfaces.

Rims may become damaged from impacts, such as hitting a rock, pothole or curb. Impacts to the side of the rim from falling down or crashing can also cause damage. It may be possible, in some cases, to repair the wheel with adjustments to spoke tension. Begin by checking relative tension in the damaged area. For example, if a wheel deviates in one section to the right, check left and right side spoke tension in that area.

Adjusting spoke tension on a wheel with a badly bent rim is unlikely to help, except possibly to get the rider home. In the above example, if a wheel deviates in one section to the right, but the spokes on the right side appear relatively loose and the spokes on the left side of the wheel appear tight, the rim metal is bent. Normally, to correct this wobble, it is necessary to tighten left side spokes, but the check showed the left side is already tight. The option of loosening right side spokes is not very effective because the right side spokes at that section are already loose. This indicates the rim has been deformed beyond the point where spoke tension can repair it.

It can happen that a spoke becomes bent or mangled. Typically, this is just a cosmetic flaw. When spokes are manufactured, they begin as stainless steel wire on huge spools. A piece of wire is cut, and a head is stamped on one end. The other end is rolled in a die to form threads. The end with the head is then bent 90 degrees. That’s it, it’s just a cold-set bend. This bend is the most severe bend the spoke is likely to see. So, if your spoke gets mangled during a crash, it is unlikely to be as severe a bend as the original factory bend. Keep riding the wheel, and one day the mangled spoke may break, but it will most likely break at the weakest point, either the factory bend, or the threads.

If the wheel is not repairable by adjusting spoke tension, the rim has been bent and will need replacement. If the old hub is in good condition, the rim can be replaced and new spokes and a new rim laced around the old hub. This process is best left to professional mechanics.

Next article in this series

Wheel Dishing (Centering) View Article

Related articles

Wheel Tension Measurement View Article

Wheel Tension App Instructions View Article

TS-2Di Dial Indicator Use in Wheel Truing View Article

In this article

Log In or Register

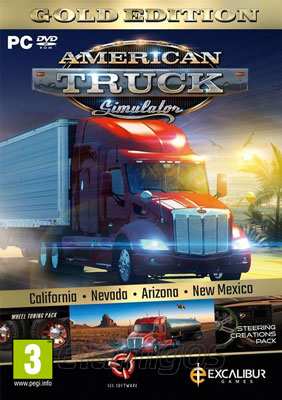

American Truck Simulator – Wheel Tuning Pack free steam key

American Truck Simulator – Wheel Tuning Pack free steam key. Free Steam KEYS! Free Steam Games. Steam Giveaways. Games Key. Free games to download. Free CD Key. American Truck Simulator – Wheel Tuning Pack steam key freeAbout American Truck Simulator – Wheel Tuning Pack key free

Ultimate wheel customization is here! Paint and customize your nuts, discs, hubs and hub covers exactly as you want.Wheel Tuning Pack includes these customizable wheel parts:

- 19 front covers

- 24 rear covers

- 14 front discs

- 17 rear discs

- 2 front hubs

- 2 rear hubs

- 10 front nuts

- 10 rear nuts

How to get American Truck Simulator – Wheel Tuning Pack cd key free

1 - First step is to register as the member2 - Choose an offer available and make sure you choose the one that's giving you lots of coins

3 - Complete the offer you have chosen, you must use real information to complete an offer / survey

Wheel Tuning Pack Bundle Crack Pc

4 - Get coins instantly to your account5 - Unlock American Truck Simulator – Wheel Tuning Pack cd key

Source: Source

- OS: Windows 7 64-bit

- Processor: Dual core CPU 2.4 GHz

- Memory: 4 GB RAM

- Graphics: GeForce GTS 450-class (Intel HD 4000)

- Storage: 3 GB available space